Shared Leadership for Lean

- islam Arid

- May 22, 2024

- 6 min read

Learn why the shared leadership culture is superior for Lean thinking compared to the traditional top-down approach and check out how to apply it in practice.

When preparing to implement Lean project management or portfolio management, you need to consider how you lead your team. Leadership is among the bases of management, and if you want the adoption of Lean to be successful in your organization, you must be ready to change for the better.

Managing a Lean team requires a shared leadership culture, and in the next paragraphs, you will learn all that you need to know to get started with it for the sake of becoming a true leader in a Lean environment.

Why Is Top-Down Leadership Not Suited for Managing Lean Teams?

For a long time, the traditional top-down leadership model was widely adopted in the majority of companies all around the world.

In the past, it served companies well because it allowed executives to hold a firm grip on the organization on every level, holding all of the decision-making power.

Although it has served well, the model is becoming outdated and impractical, especially in the context of Lean project management.

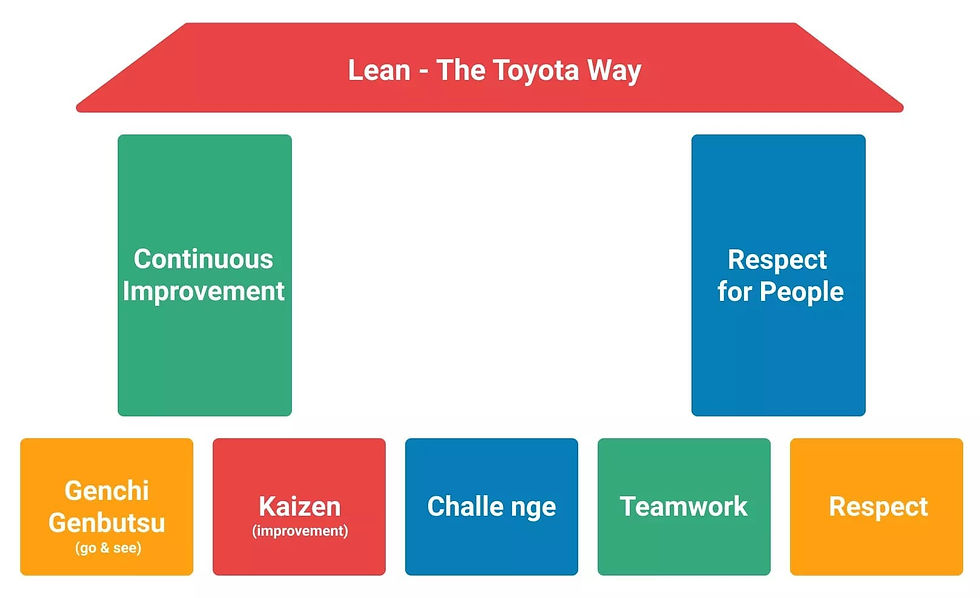

This is because of many of the common practices in traditional management conflict with the 5 principles of Lean.

There are 8 major differences between shared leadership and top-down management models. In the context of Lean, the traditional model can prove to be quite limiting since:

Handling power is often too centralized.

Information sharing is rarely encouraged.

Decision-making is a privilege provided only to management.

Feedback loops are difficult to maintain.

Arguably the greatest problem with traditional leadership is that it is extremely unsuitable for the process of continuously improving, which is vital for the successful implementation of Lean.

This is largely due to the limitations that the top-down model inflicts on the team’s actions.

For example, knowing that they have to consult a manager who needs to go to an executive for approval, even small changes often hinder regular team members' desire to suggest improvements and keep them stuck doing the same thing repeatedly.

What is Shared Leadership?

Shared leadership is based on the core idea that the leader’s primary role is to guide their team in achieving the common goal instead of being a boss and giving orders from high ground.

In the shared leadership model, the hierarchy is more informal, and the manager needs to be accepted as part of the team, not as a higher being whose approval is required for even the smallest tasks.

Leaders are driven by the shared leadership principle, radiate knowledge, and aim to provide transparency to their team. They give the whole picture to the team for the sake of better collaboration. Sharing ideas is encouraged, and the leader ensures a secure environment for this to blossom.

The backbone of the shared leadership culture is delegating responsibility throughout the organization and providing a larger number of people with the ability to execute decisions, to a certain degree, without the supervisor’s approval.

The greatest benefit of sharing leadership is that a capable and motivated team can deliver a greater amount of value in a shorter period when they are provided with more flexibility of action and are not limited by too much bureaucracy.

As a Lean manager, you need to allow and help your team take ownership of their process.

You need to encourage collaboration and provide feedback to your team regularly.

Implementing Shared Leadership in a Lean Environment

When taking the first steps in implementing Lean management, you should clarify that every person is expected to be a leader in their respective field.

This may require you to make a clear distinction between what it means to be a leader compared to being a boss.

If your team has become used to the top-down model, this transition might take time and a lot of encouragement at the beginning.

Share the Responsibility of Identifying the Value of Your Work

You need to help your team understand the value that they produce to your organization's end customer and encourage them to look for ways to enhance it.

Familiarize your team with the activities that Lean considers waste, and discuss how you can focus more on the ones that bring the most value to your customer.

Help each person understand how they fit in the value generation process and identify and polish their individual value contribution.

Be watchful for organizational silos and push out the silo mentality for the sake of improving collaboration. You don’t want the “this is not my job” attitude in your team, so be sure to get your whole team on the same page.

Map value Streams Together

After the value of your team’s work is identified, you should map the value stream of your process. Although you probably understand your process perfectly, this is not a responsibility that should be borne only by the manager.

Your front-line heroes are the people who keep it running every day and face problems that may not always come to your attention, so you should break it down and visualize it collectively.

If you organize your work on a Kanban board, after the team gets familiar with the way it works, discuss possible changes to the steps of your process and give them the liberty of suggesting improvements.

This is especially important for cross-functional teams that consist of people from different areas of expertise (e.g., marketing, RnD, sales).

If you are in the process of forming a new team of this sort, gather every person who is going to be on it together and provide them with the liberty of developing the collaboration process on their own.

As a formal leader, you should either approve their developed scheme or suggest how to improve it if there are flaws.

Create a Flow Collectively

In Lean management, creating and maintaining a flow of work is crucial. Although establishing it is more of a manager’s responsibility, your team must become the owner.

They should be aware of how the whole team's assignments are progressing and be watchful for blockers.

By adopting a culture of shared leadership, you should give them enough flexibility to relocate capacity on their own for the sake of dealing with flow issues.

For example, if the process is blocked because the team member who is responsible for executing a task is absent, another member with spare capacity and adequate expertise should have the liberty to go ahead and finish the task without having to ask you for explicit permission.

This doesn’t mean that they shouldn’t inform you about this and share their plan of action, but they shouldn’t be forced to ask for permission to ensure the smooth flow of work.

Allow Your Team to Pull Assignments

When the flow is achieved, you should set up a pull system of work, which is another key aspect of Lean management that can prove to be quite impossible with the traditional leadership model. This is among the most difficult changes for managers who are used to delegating work all the time.

Pull is a system with a limit on the work that can be in progress simultaneously.

This way, everyone focuses on one thing at a time and only starts working on new assignments when they can process them without abandoning something that is currently in progress.

Therefore, the tasks are pulled from the backlog instead of being pushed into the process, causing the abandonment of unfinished work.

Simply said, instead of constantly trying to look for free people and push work into their hands, by adopting a culture of shared leadership, you should be confident that they will find work when they are done.

Create a Sustainable Environment for Continuous Improvement

Arguably the most important benefit of the shared leadership model for Lean management is that it allows continuous improvement to blossom. It allows each team member to take ownership of their process.

This is because they will have more room to improve by providing them with the liberty of making some decisions and therefore strive to become better at what they do so they can show that the trust is well-placed.

Individual improvement is just one side of the coin. Your team will feel more secure suggesting improvements to their workflow and conduct experiments.

Nonetheless, when they have ownership of their workflow, they will be able to continuously develop as a group and achieve a symbiosis of their actions.

As a result, their way of collaboration will constantly evolve. They will be able to complement each other naturally, and your role will become more of a leader and less of a manager.

You won’t be bothered with small issues and will be able to focus on value-adding activities.

In Summary

Adopting a culture of shared leadership is an unavoidable and inseparable part of Lean management. Although in the beginning, it might be hard to let go of your old ways of leading people, you will be able to see the benefit of it very quickly because:

Your team will be more aware of the value they produce and will feel free to look for ways to enhance it.

You will improve the connection between you and each member by allowing them to take ownership of their work and share ideas.

You won’t be the sole person responsible for maintaining the flow of work.

It will be easier to maintain a pull system.

You will have a suitable environment for continuous improvement.

Comments