TQM elements:

- islam Arid

- Dec 11, 2023

- 14 min read

Updated: Dec 13, 2023

Comprehensive Course on Enterprise Risk Management

Our courses :

Introduction:

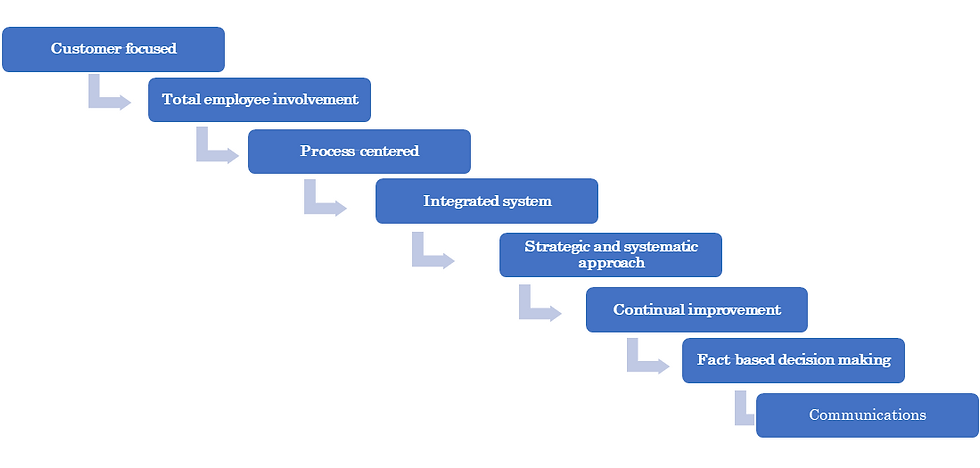

Today, we're diving into a Total Quality Management element and how to implement it. TQM is a comprehensive approach that involves every member of an organization in the pursuit of excellence. In this session, we'll explore the eight key elements that make TQM so essential for success.

1. Customer-focused:

Let's start with the first element of Total Quality Management which is customer focus. In TQM, the customer is at the heart of everything. It's not just about making products or providing services It's about meeting or even exceeding customer expectations. Every action, decision, and process within an organization should revolve around ensuring customer satisfaction. After all, happy customers are loyal customers, and they drive the success of any business.

To implement this TQM principle:

let's explore the steps an organization can take to implement this crucial principle effectively.

o Research and Understand Customer Needs and Expectations:

The first step in implementing customer focus is to get to know your customers intimately. This involves conducting thorough research to understand what your customers truly need and expect from your products or services. This valuable information can be gathered through surveys, focus groups, direct customer interviews, and other methods. The goal is to gain insights into their preferences, pain points, and expectations.

o Align Organizational Objectives with Customer Needs:

Once you've gained a deep understanding of your customers, it's time to align your organization's objectives with their needs and expectations.

This involves ensuring that your products and services are designed and delivered in a way that meets or even exceeds customer expectations.

o Communicate with Customers, Measure Satisfaction, and Use the Results to Improve Processes:

Continuous communication with your customers is key to maintaining a customer-focused approach. Engage with your customers through surveys, social media, and other channels to gauge their satisfaction. Collect their feedback, and most importantly, use this feedback to improve your processes and make necessary adjustments.

o Manage Customer Relationships:

Building and maintaining strong relationships with your customers is vital. Provide exceptional customer service, respond promptly to complaints and concerns, and consistently strive to exceed their expectations. A satisfied customer is more likely to become a loyal one.

o Find a Balance for Satisfying Customers and Other Interested Parties:

Find a balance for satisfying customers and other interested parties. While customer satisfaction is paramount, it's also important to strike a balance that benefits everyone involved. Consider the needs and interests of other stakeholders such as owners, employees, suppliers, and investors when making decisions. Finding a win-win solution that benefits both customers and the organization is the ultimate goal.

The benefits of being customer-focused include:

Now, let's explore the incredible benefits that come with being customer-focus

o More Sales, Increased Revenue, Market Share, and Mindshare:

When an organization consistently meets or exceeds customer expectations, the rewards can be significant. Satisfied customers are more likely to choose your products or services over competitors'. This translates to increased sales, revenue, a larger market share, and a strong presence in the minds of your target audience.

o Strong Customer Loyalty Leading to Repeat Business:

Simply Customer loyalty is a treasure for any business. When you consistently deliver what your customers want, they become loyal to your brand. Loyal customers are more likely to return for future purchases, reducing the need for costly acquisition efforts.

o Increased Possibility That Satisfied Customers Will Tell Others About Your Products and Services:

So, Word-of-mouth marketing is incredibly powerful. When your customers are not just satisfied but delighted with your products and services, they become your best advocates. They'll naturally spread the word about their positive experiences to friends, family, and social networks.

2. Total employee involvement:

Now, let's delve into another element of Total Quality Management which is Total Employee Involvement. This principle signifies that every employee, regardless of their role or level, is actively engaged and committed to achieving the organization's objectives. Total Employee Involvement isn't just a catchphrase; it's a philosophy that can transform an organization from the inside out.

To implement this TQM principle:

Now we will move on to how to implement it.

o Clearly communicate and acknowledge the importance of each individual contribution to the completed product.

Every employee's work matters, and they need to know it. Employees should understand how their contributions fit into the bigger picture. Recognizing their efforts fosters a sense of pride and motivates them to give their best.

o Stress that each team or individual accepts ownership and gives them the responsibility and opportunity to solve problems when they arise.

Empowerment is key to commitment. Empowered employees feel a sense of ownership and are more committed to solving problems and improving processes. They become proactive contributors to the organization's success.

o Encourage employees to self-evaluate performance against personal goals and objectives and make modifications as necessary to improve workflow.

Personal improvement leads to organizational improvement. When individuals take responsibility for their own growth and performance, it contributes to a culture of continuous improvement.

o Acknowledge successes and optimize performance to build confidence in your employees and your stakeholders.

Celebrate the wins. Recognizing and celebrating achievements not only boosts employee morale but also demonstrates that their efforts are valued and lead to positive outcomes.

o Make responsibilities clear, provide adequate training, and make sure your resources are used as efficiently as possible.

Everyone needs to know what is expected of them and how to do their job well. Clear expectations and proper training are essential. When employees are confident in their roles, they can perform their tasks efficiently and contribute effectively.

o Encourage people to continually seek opportunities to learn and move into other roles to increase their knowledge, competence, and experience.

Lifelong learning is essential. A culture of continuous learning keeps employees engaged and adaptable. It's an investment in both individual and organizational growth.

o Create an environment where employees can openly discuss problems and suggest ways to solve them.

Communication is vital to continuous improvement. Encouraging open communication allows for the sharing of ideas, identifying issues early, and collectively finding solutions to improve processes.

The key benefits of total employee commitment include:

Let's uncover the benefits of fostering total employee commitment within your organization.

o Increased employee retention:

When employees are motivated, committed, and actively involved in working toward customer satisfaction, they're more likely to stay with the organization. High employee retention not only saves on recruitment costs but also creates a stable and experienced workforce.

o Individual and team innovation and creativity:

Total employee commitment encourages innovation and creative problem-solving. When employees are empowered to contribute their ideas and insights, they often come up with innovative solutions and process improvements that can set your organization apart.

o Employees who take pride and accountability for their own work.

Total employee commitment fosters a sense of ownership and responsibility. When individuals feel a personal connection to their work, they are more likely to deliver high-quality results and take ownership of their tasks.

o Enthusiasm for active participation and contribution to continual improvement.

When employees feel valued and engaged, they are more likely to go the extra mile. An enthusiastic workforce actively contributes to the organization's journey of continuous improvement, driving positive change and excellence. Incorporating total employee commitment into your organization's culture isn't just about achieving specific goals; it's about reaping these remarkable benefits.

3. Process-centered:

Another key element of Total Quality Management is being process centered. This means that, at its core, TQM is all about process thinking. A process, in TQM terms, is a series of well-defined steps that take inputs from suppliers, whether they are internal or external, and transform them into outputs that are delivered to customers, again, whether they are internal or external. What makes being process-centered so important in TQM is that the steps required to carry out the process are clearly defined, and performance measures are continuously monitored to detect any unexpected variation. This process-centric approach is vital because it shifts the focus from just achieving an end result to understanding and improving the steps involved. When we prioritize the process, we ensure that each step is efficient, effective, and aligned with quality standards. This, in turn, leads to a more consistent and high-quality end result.

To implement this TQM principle:

Now, how to implement the process centric approach effectively.

o Use Total Quality Management tools such as process flowcharts

To define and clear roles and responsibilities, ensuring that everyone knows who does what at specific times, process flowcharts are invaluable tools for visualizing and documenting each step in a process. They make it crystal clear who is responsible for each part of the process and what should be done next.

o Create a visual action plan

so that everyone can easily see the specific activities required to achieve the desired result. Visual action plans provide a roadmap that keeps everyone on the same page. They ensure that no crucial step or detail is missed, enhancing collaboration and efficiency.

o Analyze and measure current activities:

to identify areas for improvement and bottlenecks in the process. By scrutinizing each step of the process, we can pinpoint areas where improvements can be made. Eliminating bottlenecks and inefficiencies can lead to smoother operations and improved productivity.

o Evaluate the impact your processes and activities may have on all stakeholders,

including customers, suppliers, and everyone involved. When we consider the needs and expectations of all stakeholders, We ensure that we're delivering the best possible experience to them. It's about meeting their needs and creating a harmonious relationship.

By implementing these practices, we can reap the following benefits:

o Faster development and production cycles, lower costs, and increased revenue.

By focusing on the process, we can achieve remarkable improvements in efficiency. When processes are optimized, waste is reduced, and inefficiencies are eliminated. This results in faster development and production cycles, ultimately leading to lower costs and increased revenue.

o More consistency and predictable outcomes.

By Defining the process and monitoring performance measures ensure that the process is consistent. With a well-defined and monitored process, you can expect more consistent and predictable outcomes. This reliability builds trust with customers and stakeholders.

o Focus on continued improvements and success.

Continuous analysis and improvement are at the heart of TQM. By continually analyzing and improving the process, you not only achieve success but also maintain a competitive advantage in an ever-evolving marketplace.

4. Integrated system:

In today's competitive business landscape, organizations resemble intricate puzzles with multiple pieces, each representing a different department, specialty, and role. These functional specialties are often organized into vertically structured departments. Yet, the real magic happens when these separate elements connect and integrate seamlessly to form a unified whole. This is where Total Quality Management (TQM) comes into play. It's all about focusing on the horizontal processes that interconnect these functions. TQM is the art of improving an organization by understanding that micro-processes add up to larger processes, akin to fitting together the pieces of a puzzle. Each microprocessor is a piece, and when combined, they form a more significant whole. Just like a city's roads connect neighborhoods and districts, these micro-processes aggregate into the business processes required for defining and implementing strategy. A well-integrated system ensures that everyone in the organization works together towards a common goal, which is to provide value and quality to the customer.

How to achieve an integrated system within your organization

Creating an integrated system within your organization is not just a goal; it's a necessity. Here's how you can achieve it.

o Step one, promote a work culture focused on quality.

In an integrated system, Quality should be the concern of every member of your organization, not just a select few.

o Step two, use flowcharts and visual aids to help employees understand their role in the bigger picture.

Clear visual representations make it easier for everyone to see how they fit into the overall process.

o Step three, employ process analysis to identify areas for improvement.

By analyzing the existing processes, we can identify areas where improvements can be made, which leads to a more efficient and effective system.

o Step four, make training available to empower your employees.

Offer training for those who need to learn new processes and those who aspire to advance their careers.

Benefits for integrated system within your organization

By implementing these steps, you're not just creating an integrated system; you're fostering a culture of continuous improvement and collaboration, where every member is an integral part of your organization's success. Firstly, better coordination and communication across different departments foster a culture of collaboration and teamwork. Secondly, you'll witness higher efficiency and productivity, resulting in reduced costs and increased revenue, as every part of your organization works in harmony. Lastly, improved quality and customer satisfaction become the hallmark of your integrated system. This, in turn, leads to increased customer loyalty and repeat business.

5. Strategic and systematic approach:

Let's delve into another crucial element of Total Quality Management: the strategic and systematic approach. This principle is all about aligning processes, resources, and people with the organization's vision, mission, and goals. In simpler terms, it means ensuring that every aspect of the organization works together harmoniously to achieve its objectives and deliver value to customers and stakeholders. From the perspective of ISO, identifying, understanding, and managing interrelated processes as a system is fundamental to an organization's effectiveness and efficiency in achieving its objectives. Think of an organization as a grand puzzle where every piece, be it a process, resource, or individual, fits into the larger picture. When each piece is strategically placed and functions systematically, the overall outcome is a clear and cohesive path towards the organization's goals. Incorporating a strategic and systematic approach isn't just about setting goals; it's about ensuring that every element of your organization aligns to reach those goals effectively and efficiently.

How To implement Strategic and systematic approach principle:

Step 1: Provide Proper Training and Resources.

To achieve quality objectives, employees need the right skills, knowledge, and tools to perform their jobs. It's essential to invest in training programs, coaching, and mentoring to help employees develop their competencies and keep up with the changes in technology, regulations, and customer requirements. By providing proper resources, such as equipment, software, and materials, you can also ensure that employees have the means to ensure quality and efficiency.

Step 2: Continually Improve Processes and Products.

In a dynamic and competitive environment, organizations need to innovate and improve continuously. Use feedback, data, and metrics to identify areas for improvement then Implement changes that add value to your customers, reduce waste, and defects. By adopting Tools like Lean, Six Sigma, Kaizen, or PDCA you can facilitate a culture of continuous improvement.

Step 3: Make Continual Improvement a Measurable Objective.

This will help you to ensure that everyone in the organization is aligned with the strategic and systematic approach, it's necessary to set measurable objectives and targets for quality improvement. By doing so, you can track progress, identify gaps, and motivate employees to strive for excellence. For example, you can use Key Performance Indicators (KPIs) such as customer satisfaction, defect rate, cycle time, or cost savings to measure the effectiveness and efficiency of your quality management system.

Step 4 - Recognize, Acknowledge, and Reward Innovations and Process Improvements. Encourage a culture of continuous improvement.

To encourage a culture of continuous improvement, it's essential to recognize and reward employees who come up with innovative ideas or improvements that add value to the organization. By doing so, you can create a sense of ownership and pride among employees, foster teamwork and collaboration, and stimulate creativity and engagement. Rewards can take different forms, such as bonuses, promotions, public recognition, or opportunities for professional development.

Benefits of a Strategic and systematic approach include:

First, a strategic and systematic approach enables quicker identification, reaction, and resolution of process bottlenecks or breakdowns. Next, it promotes increased alignment of processes, resources, and people with your organization's goals and objectives. Moreover, it leads to improved customer satisfaction, higher employee engagement, and greater trust from your stakeholders. Lastly, embracing a strategic and systematic approach enhances your competitiveness and ensures long-term sustainability in an ever-changing marketplace. When you adopt this approach, your organization becomes a well-oiled machine, where challenges are swiftly addressed, goals are pursued with precision, and everyone reaps the rewards

6. Continual improvement:

Continual improvement drives an organization to be analytical, constantly seeking data-driven insights to refine its operations. But it's not just about numbers. It's also about being creative in finding innovative ways to meet stakeholder expectations. Simply It's a two-fold approach, where organizations must be analytical in analyzing data and processes, but also creative in finding innovative solutions. A significant aspect of TQM is continual process improvement, where businesses should consistently seek ways to enhance processes and adapt products and services as customer needs evolve. It’s not a one-time project; it's an ongoing commitment to excellence.

Now let's jump to the implementation

First, implement policies to establish product, process, and system improvements as measurable goals for individuals, teams, and departments. Next, recognize, acknowledge, and encourage innovation. Encouraging your employees to think creatively and suggest ways to improve processes and development can lead to remarkable advancements. Lastly, foster a learning culture. Encourage employees to participate in available training sessions to learn new skills and take on new and additional roles.

Benefits of Continual improvement include:

First and foremost, continual improvement leads to improved knowledge and capabilities, resulting in enhanced performance. Your team becomes better equipped to tackle challenges head-on. Secondly, improvement goals are strategically aligned with your organizational capabilities and goals. It's like having a GPS that keeps your organization on the right track. Lastly, continual improvement equips your organization with quick reaction times to recognize and fix bottlenecks and broken processes. It's all about staying agile and efficient.

7. Fact-based decision making:

Fact-based decision-making emphasizes that analysis and data gathering are the cornerstones of making informed and effective decisions In TQM, organizations are required to continually collect and analyze data to enhance decision-making accuracy. Data isn't just a set of numbers; it's a powerful tool that allows organizations to make decisions based on available information by analyzing historical data, organizations can anticipate future trends and make proactive decisions to stay ahead

To implement the Fact-based decision-making principle:

o Step 1: Analyze and Check Data for Reliability and Accuracy.

Begin by analyzing and thoroughly checking the data you're working with to ensure it is reliable and accurate.

Informed decisions are only as good as the data they're based on.

o Step 2: Make Relevant Data Available to Stakeholders.

Transparency is key. Make relevant data readily accessible to stakeholders, ensuring everyone is on the same page and can contribute to the decision-making process.

Step 3: Use Valid Methods to Gather and Analyze Data.

Ensure that the methods used for data gathering and analysis are valid and reliable.

Garbage in, garbage out - quality data collection is paramount.

Step 4: Make Decisions Based on Data, Experience, and Intuition.

Embrace the holistic approach

make decisions not just based on data, but also with consideration of your experience and intuition.

The synergy of these elements leads to well-rounded decisions.

Benefits of Fact-based decision making include:

Fact-based decision making empowers you with the ability to make informed decisions. Your choices are rooted in data, making them more reliable and strategic. Furthermore, it grants you the ability to analyze and defend past decisions by referencing factual records. This means your decisions can withstand scrutiny and skepticism. Not only that, but fact-based decision also making allows you to adapt. You have the ability to change past decisions based on data review, ensuring your organization stays agile and responsive.

8. Communications:

Transparency is the key. Everyone, from the top to the bottom, needs to be on the same page when it comes to plans, strategies, and methods for achieving goals. It all starts with clear communication. Leaders must ensure that plans and strategies are effectively conveyed to the entire team. A visual representation, like a flowchart, can be invaluable. It helps everyone see how individual efforts align with the overarching strategies and goals

To implement communication principle:

First, establish an official line of communication. Ensure that all employees are kept informed about updates, policy changes, and new processes through regular, transparent communication channels. Second, involve employees in decision-making whenever possible. Their insights and perspectives can be invaluable in shaping the direction of your organization. Lastly, make sure everybody in every department understands their roles and how they fit into the larger company structure. Visual aids, like diagrams, can help illustrate this.

Benefits of communication include:

First and foremost, communication boosts morale and motivation. When employees understand how their contributions align with the company's goals, they feel valued and inspired to excel. It’s not just about individuals; it's about the entire team. Communication fosters interdepartmental coordination and cooperation, breaking down barriers and silos. Elimination of silos which means information flows freely, leading to a more accurate measurement of the effectiveness of current policies and procedures. Lastly, communication instills higher motivation in employees to achieve goals. They become part of the decision-making process, making success a shared endeavor.

At the end:

o Total Quality Management is a comprehensive approach to quality management that involves all employees in an organization. Thank you for watching, and we hope you found this video informative. Don't forget to like and subscribe for more content like this!

Our courses :

Hashtags:

#qualitytime #qualitycontrol #qualityoflife #qualityeducation #qualitymatters #qualityfirst #qualitywigs #equalitymatters #racialequality #swissquality #qualitysleep #qualityused #qualitycars #qualitytimes #qualitycoffee #qualityguaranteed #qualityusedcars #foodquality #finestquality #highqualitybag #starquality #affordable #prochoice #equity #inclusive #antiracism #kissmylook #lesbianvids #bagsandpurses #abortionisnormal #familia #m #sixsigma #fiel #sentimental #elloko #gracias #thefool #leadership #kaizen #kanban #pdca #dmaic #qualityassurance #hff #o #leanmanufacturing #leansixsigma #tequiero #justintime #vsm #iatf #jit #qms #qualitycontrol #leantools #hermosa #capa #sampling #h

Comments